About M5

M5 is the makerspace of the Department of Electrical and Computer Engineering at UMass Amherst.

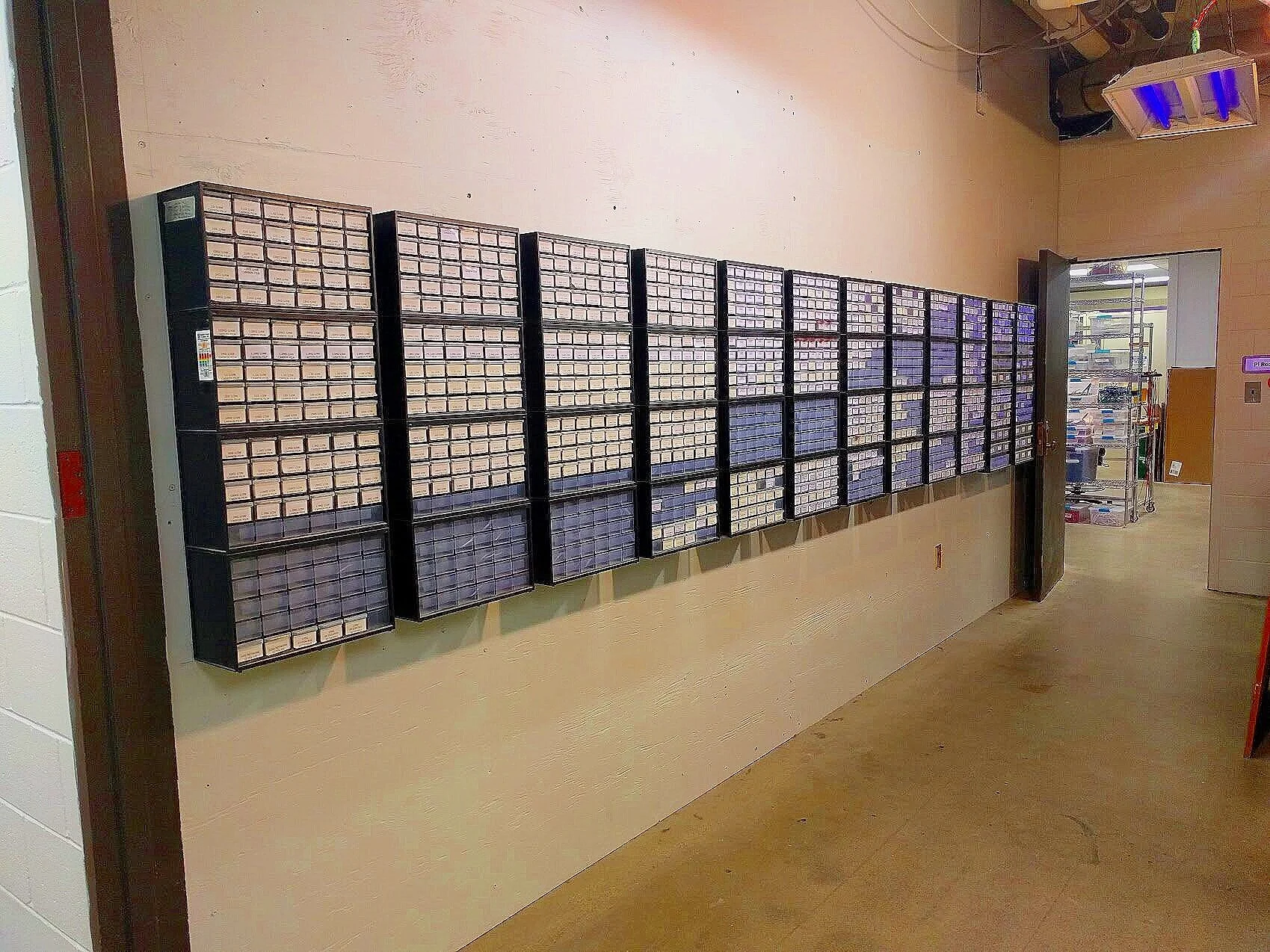

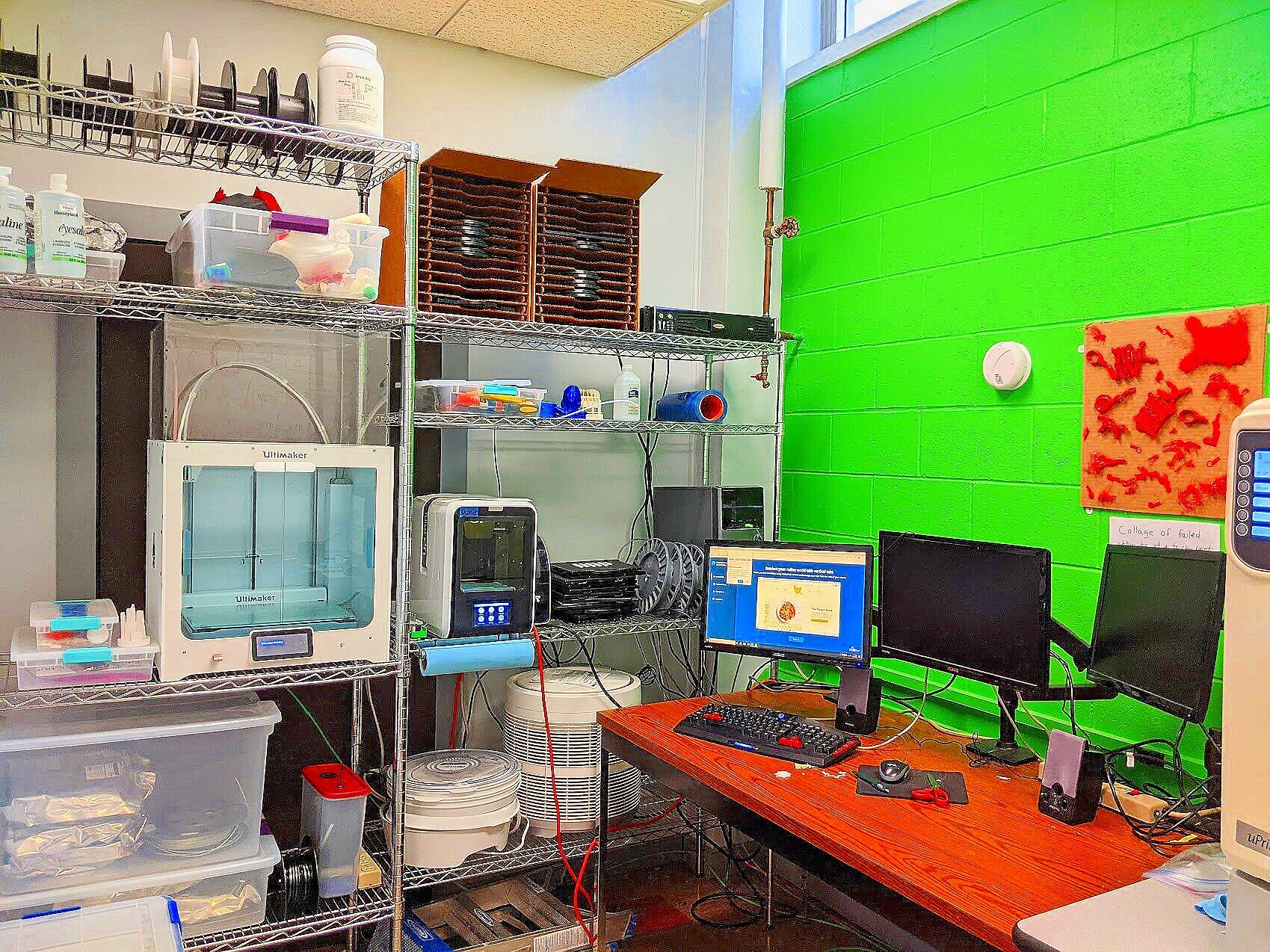

Opened in 2008, the 5,000 sq. ft. makerspace is an educational initiative that provides new dimensions to the UMass Amherst ECE experience.

M5 enables ECE undergraduates students, graduate students, faculty, and staff to advance their technical interests through experimentation, exploration, social interaction, and entrepreneurship.

M5 integrates laboratories, meeting rooms, and a demilounge to support a broad range of individual and collaborative activities, formal and informal instruction, and mentoring.

M5 is made possible through the generous support of the ECE alumni, the College of Engineering, the Department of Electrical and Computer Engineering and our corporate partners.

M5 is located on the lower level of Marcus Hall, 100 Natural Resources Road.